Filter material G4 20 mm, 1000×1000

Reference: FMAT20G41000

£5.17

delivery in 5-7 working days

Ex VAT: £4.31

| Filter dimensions | 1000x1000x20 |

| Class EN779 | G4 |

| Class ISO16890 | Coarse 65% |

| Protection level | Basic: larger solid particles, dust, fluff. |

| Quantity of filters | 1 |

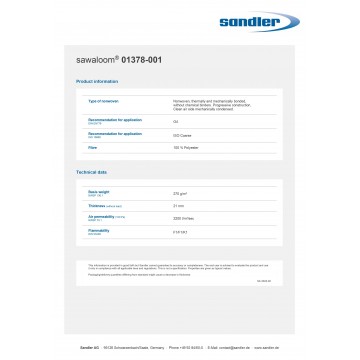

| Advantages | check Low airflow resistance: longer servicing term, lower energy consumption. check Made in the EU. check Premium class safe synthetic filtering material from SANDLER AG (Germany) |

| Remarks | check Cut out required filter dimensions using knife or the other sharp object. check In ventilation devices filtering material is used with filter frames only. |

FMAT20G41000

Data sheet

- Manufacturer of MVHR

- Sandler

- Filter dimensions

- 1000x1000x20

- Class EN779

- G4

- Class ISO16890

- Coarse 65%

- Protection level

- Basic: larger solid particles, dust, fluff.

- Quantity of filters

- 1

- Advantages

- Low airflow resistance: longer servicing term, lower energy consumption.

Made in the EU.

Premium class safe synthetic filtering material from SANDLER AG (Germany) - Remarks

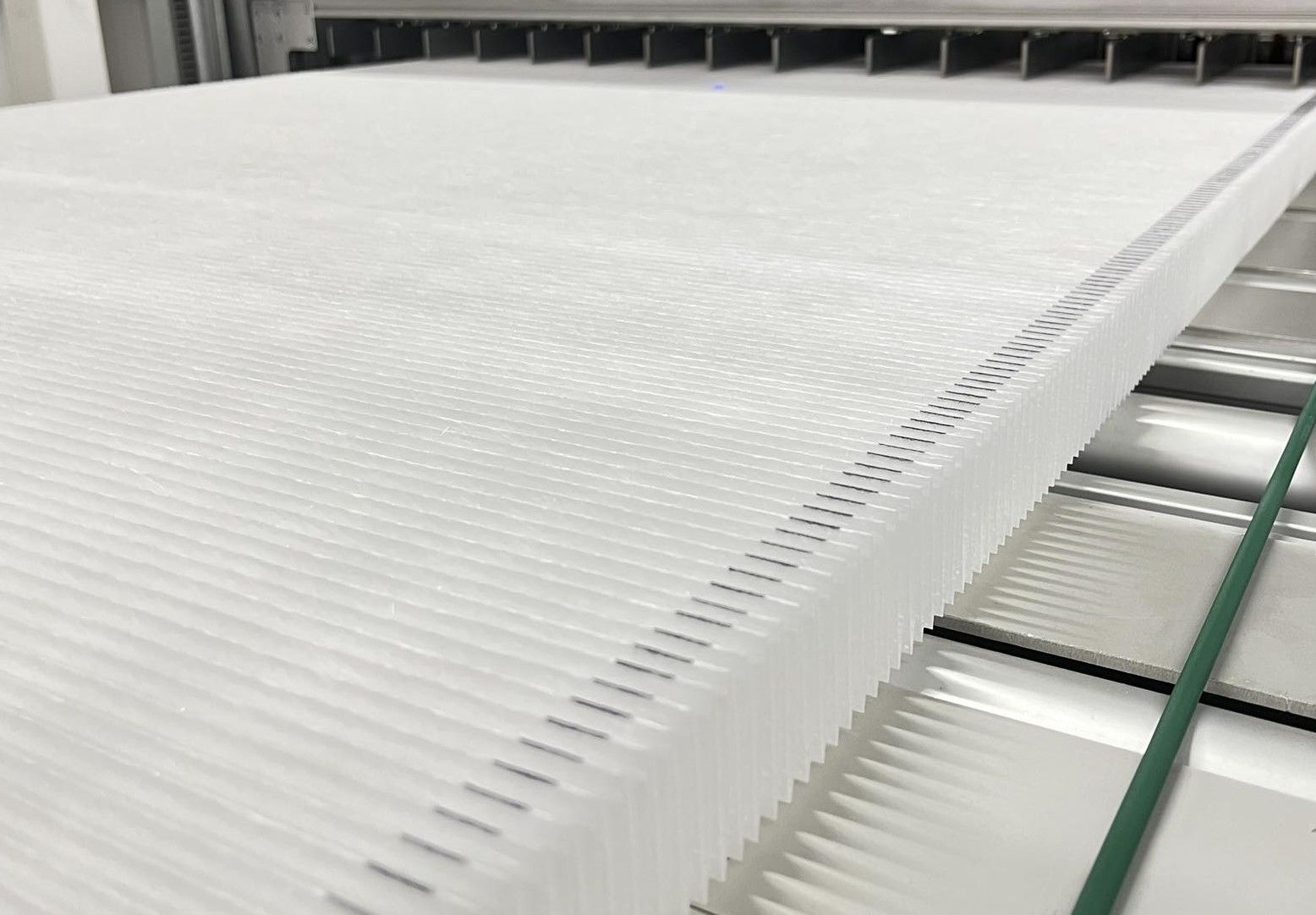

- Cut out required filter dimensions using knife or the other sharp object.

In ventilation devices filtering material is used with filter frames only. - Google category ID

- 3573

- Product type

- Filters for Air Handling Units